The reliability of electronic assemblies is a crucial factor in the planning, lifespan, and smooth operation of drive systems. It is directly related to the failure rate: higher reliability means a lower failure rate of the drive system, as it reduces the probability of failure within a given period. This tutorial answers fundamental questions about assessing the reliability and failure rate of electronic products from FAULHABER.

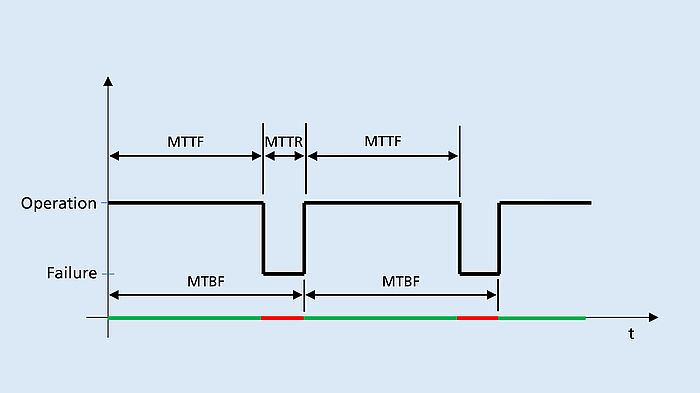

The reliability of electronic components such as controllers and encoders can be assessed using the metrics MTTF, MTBF, and MTTR. Figure 1 graphically illustrates these three metrics in relation to operation and failure over time.

The “Mean Time To Failure” (MTTF) describes the average operating time until a failure occurs and is particularly relevant for assemblies that cannot or should not be repaired or maintained. This metric provides insight into the fundamental reliability of a product and aids in long-term planning.

According to EN ISO 13849-1, it is assumed that 50% of all failures are hazardous. Therefore, safety-related systems, where failure is particularly critical, are evaluated using MTTFD (D = dangerous), which is twice the MTTF.

“Mean Time Between Failures” (MTBF) refers to the average time between two failures in assemblies that are subject to maintenance, such as replacing relays after a specific number of switching cycles. MTBF is particularly important for systems where operational continuity is maintained through quick repairs.

The “Mean Time To Repair” (MTTR) represents the time required to replace or repair a defective component. A lower MTTR minimizes downtime and is an essential factor in service planning.

The failure rate (λ), also referred to as the error rate, is used to evaluate the reliability of a component. It helps to estimate the probability of a system failure per unit of time. The failure rate is typically expressed in FIT (Failures In Time), where 1 FIT corresponds to one failure per billion operating hours. The failure rate is a crucial metric for assessing system reliability.

FIT (Failure In Time) and MTTF (Mean Time To Failure) can be converted into each other:

MTTF = 1 / λ

MTTF in years = 1 / (λ x 8760 h/year) [where 1 year = 8760 hours]

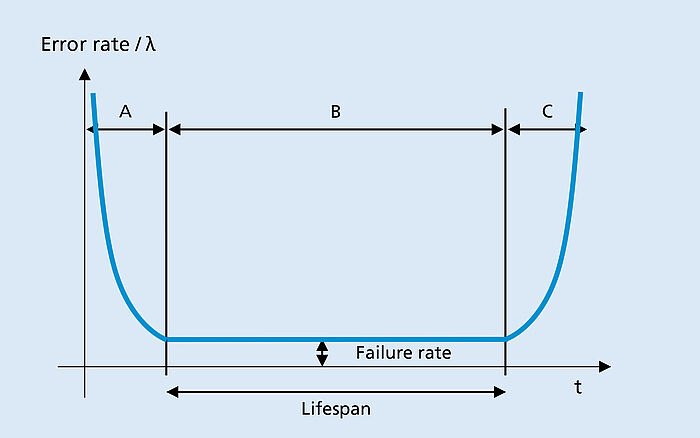

The failure rate is graphically represented by the "bathtub curve", which illustrates the (observed) failure rate of a technical device throughout its lifecycle. This curve consists of three phases:

1. Early Failure Phase (A): Failures in this phase are typically due to manufacturing defects, transport damage, incorrect connections, or mishandling. The higher initial failure rate, which is characteristic for this phase, can be reduced through quality assurance and testing.

2. Constant Failure Rate (B): In phase B, the failure rate remains constant. It is described using the Mean Time To Failure (MTTF) defined in chapter 1, which corresponds to the stable service life of a product.

3. Wear-Out Phase (C): At the end of a product's lifespan, failure rates generally increase due to material fatigue or aging processes. However, for electronic components, which are the main focus of this tutorial, this phase is typically negligible.

The failure rate (λ) of an electronic component significantly affects the reliability of the entire drive system or a complete installation. By knowing the MTTF values of all used components, operational uptime can be optimized:

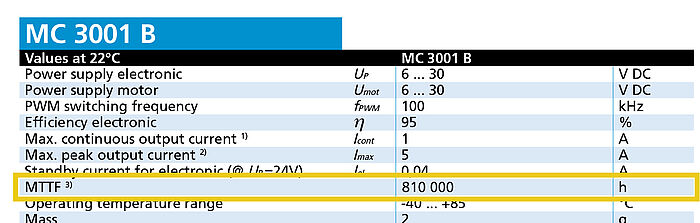

The MTTF value can be found in the list of key data in the upper section of the corresponding FAULHABER data sheets.

Most FAULHABER electronic products feature reliability values in their data sheets.

These values are determined using the Parts-Count Method, which involves calculating the MTTF value for each individual component based on a bill of materials.

Example calculation of MTTF for a metal film resistor

λRESISTOR = 0.2 x 10⁻⁹ 1/h (or 0.2 FIT) [Source: SN 29500-4, Table 2]

This results in the following MTTF calculation:

MTTFRESISTOR = 1 / (0.2 x 10⁻⁹ h⁻¹ x 8760 h/year) = 570,776 years

For active semiconductor components, data from semiconductor manufacturers is used (whenever available), as it is based on empirical testing. Additional required values are derived from Siemens standards (SN 29500 1-12). To account for environmental conditions such as temperature and load levels, the Siemens standard incorporates derating factors for voltage, current, and temperature into the calculations.

The MTTF values specified in the FAULHABER data sheets are calculated based on nominal operation at the maximum permissible supply voltage.

The total reliability λtotal is obtained by summing all individual FIT values and is then converted into MTTF in hours or years using the formulas from chapter 1.

The Parts-Count Method should be regarded as a purely statistical approach that enables probabilistic assessments of failure rates in complex systems.

It is crucial to note that the calculated MTTF value should not be confused with the minimum lifespan of a component.

Would you like to learn more about the reliability values of our electronic products or find a data sheet for a specific product? Or do you need assistance in selecting the right electronic drive components for your project?

The FAULHABER sales engineers are happy to assist you. Let us work together to find the optimal solution that meets your specific requirements, environmental conditions, and technical challenges.