High-quality linear actuators are tiny powerhouses: Despite their compact size, they support high input speeds and, at the same time, deliver high output forces. When selecting a linear actuator, it is advisable to adopt a systematic approach and to precisely determine which model can deliver the required power and also reliably withstand power peaks.

Below you will find out:

2. How to calculate the speed and torque for a planned application.

The FAULHABER Drive Calculator makes choosing the right linear actuator easy: This free online tool for selecting drives helps you find perfectly tailored solutions for the concrete application case. To use the Drive Calculator efficiently for calculating linear actuators, you will need some key data.

In this tutorial, we guide you through five basic steps for linear actuator selection and show you how to determine the parameters required for calculating the drives.

To make it easier for you to apply these five steps to your own projects, we will demonstrate how to select a linear actuator for a specific application based on a concrete example.

Depending on your planned application, certain mechanical prerequisites may exist from the outset, which limit your choice to linear actuators with certain features. For example, it is often the case that a certain type of lead screw is essential or that the space available for the drive is limited. To ensure that your shortlist contains only models that meet these basic prerequisites, it is worth starting the selection of a linear actuator with the creation of a requirement profile for the planned application.

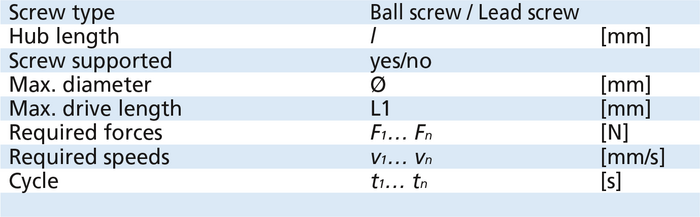

In addition to factors such as lead screw type, stroke length and diameter of the linear actuator, we also recommend that you note down the required forces and speeds as well as the planned cycle. This will then allow you to determine the products which are right for your application more easily. Figure 1 shows a blank version of such a requirement profile.

Basic parameters such as the lead screw type, stroke length or diameter of a linear actuator can be found in our data sheets. Using this data, you can compare the requirement profile for the planned application generated in the first step with the performance capability and any limits of various solutions.

Once the lead screw type and maximum diameter are known, it is usually possible to make an initial shortlist from the available linear actuators. In our example, a ball screw and a maximum diameter of 22 mm are critical for the suitability between drive and application. Here, for example, the linear actuator 22L SB xx:1 6x2 150 from the FAULHABER product range would come under consideration because it fulfills the basic parameters.

For reasons of clarity, however, our application example is based on only a small number of selected standard application parameters. Depending on the type of application you are planning and the environment in which it is to be used, a multitude of other factors - e.g. system accuracy, temperature range or used materials - may be of central importance for linear actuator selection. The data table shown here as well as the following four calculation steps are therefore intended only as a guide for an initial assessment of potential solutions.

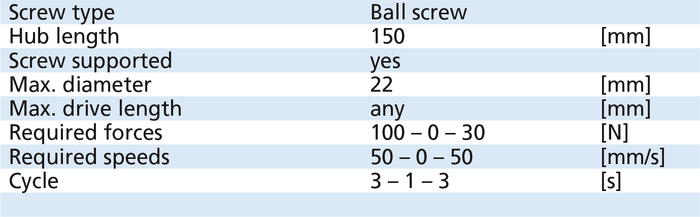

Later in the tutorial, we will use an example application to show you how you can check in a specific case whether your favored model meets the requirements of the planned application. In this example case, the application has the following basic data:

When selecting the appropriate linear actuator, the motor with which the linear actuator is to be combined also plays a key role. If the motor is not powerful enough for the planned application, it will constantly overheat during operation. Consequently, additional heat is transferred to the linear actuator - and this reduces the effectiveness of the lubricant and, as a result, can shorten the service life of the entire device combination. For this reason, it is advisable to ensure that the motor does not exceed a temperature of 60 °C to 70 °C in continuous operation and in doing so to prevent premature degradation of the lubricant.

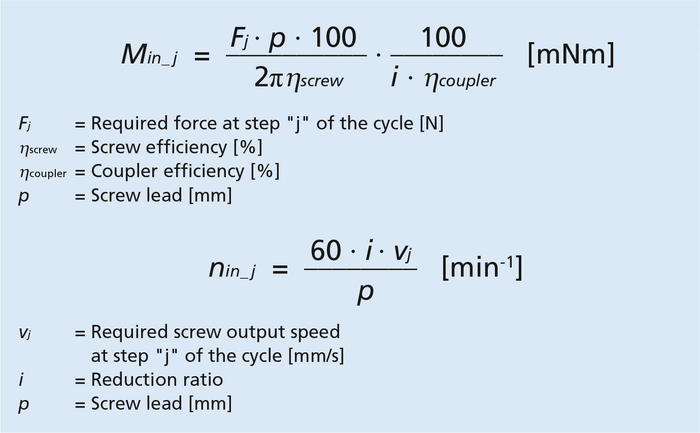

For each of the available solutions, the input speed and the input torque must be calculated using the following formulas:

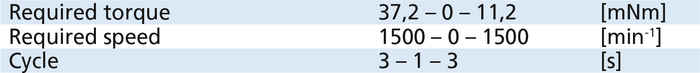

In our example, the torque and speed at the input of 22L SB 1:1 6x2 150 have the following values during the cycle:

The motor can then be selected according to the relevant technical information of each motor family.

After you have identified the linear actuators that fulfill the basic mechanical parameters of the planned application, you now need to find out which of these models can deliver the required forces and speeds. This ensures fault-free operation of your application.

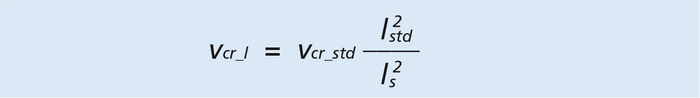

In the data sheet of the linear actuator, check the actual critical lead screw speed (Vcr_std) according to the lead screw bearing system (fixed - free or fixed - single). If the stroke length differs from the standard, the actual lead screw speed Vcr can be determined using the following formula:

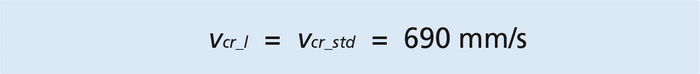

In our example, we consider the bearing version 22L SB xx:1 6x2 150, supported (fixed – single):

To make sure that no resonance problem occurs during operation of this linear actuator in the planned application, you should also check whether the critical speed is above the maximum cycle speed: Vcr_l > Vmax

In our example case, this requirement is met because the critical speed is vcr_l = 690 mm/s and therefore well above the maximum cycle speed of the linear actuator (vmax = 50 mm/s).

For each available reduction ratio, check whether the required maximum speed (Vp max) is below the specified limit (Vp max ≥ Vmax). The maximum output speed as well as the maximum continuous force range for each drive stage can be found in the data sheet of the respective linear actuator.

In our example, we refer to the data sheet of the linear actuator 22L SB xx:1 6x2 150 and note that all ratios > 6.6:1 can be ruled out.

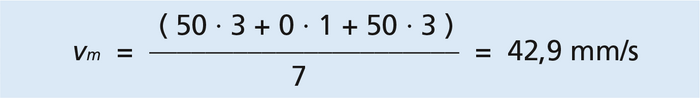

The average output speed (Vm) can be calculated using the following formula:

In our application example, the cycle input data is taken into account. This results in the following average output speed:

For each available reduction ratio, check whether the required average speed is below the specified limit (vc max > vm). For this step too, the maximum output speed as well as the maximum continuous force range for each drive stage can be found in the data sheet of the respective linear actuator.

If it is evident that that the selected linear actuator is able to achieve and maintain the required speeds, in the next step we check which forces act on the drive in the concrete configuration. As with linear speed, here too we follow three steps to determine whether the linear actuator is able to withstand the different forces that act on it during operation.

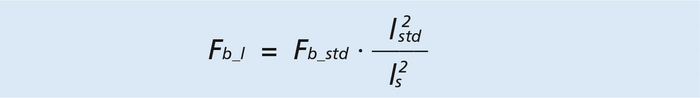

Refer to the data sheet of the linear actuator to determine the actual buckling force of the lead screw (Fb_std) according to the lead screw bearing system (fixed - free or fixed - single). If the stroke length differs from the standard, you can calculate the actual value of the buckling force (Fb) using the following formula:

In our example case, the data sheet of the FAULHABER linear actuator 22L SB xx:1 6x2 150 (fixed - single) states the following: Fb_l = Fb_std = 2562 N

We now make certain that the buckling force is above the maximum cycle force (Fb_l > Fmax), i.e. that no buckling problems will occur when commissioning the linear actuator in this application. In our example, this requirement is met because the buckling force of the lead screw of our linear actuator is Fb_l = 2562 N and therefore well above the maximum cycle force Fmax = 100 N.

For each available reduction ratio, check whether the required maximum axial force is below the specified limit (Fp max ≥ Fmax). For this calculation too, the maximum output speed as well as the maximum continuous force range for each drive stage can be found in the data sheet of the selected linear actuator. In our example, the requirement is satisfied for all ratios.

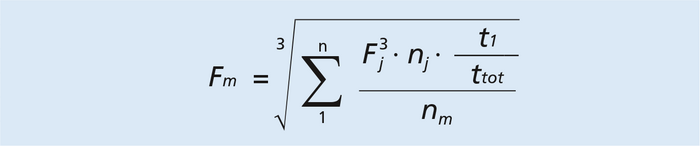

The average output force can be calculated using the following formula:

In our application example, the cycle input data for the selected model, the FAULHABER linear actuator 22L SB xx:1 6x2 150, is also used here. This leads to the following calculation:

For each available reduction ratio, we now check whether the required average force is below the specified limit (Fm max ≥ Fm). For this step too, the maximum output speed as well as the maximum continuous force range for each drive stage can be found in the data sheet of the selected linear actuator. In our example, the requirement is satisfied for all ratios.

In principle, it is possible to operate a linear actuator with a higher average axial force than specified in the data sheet of the respective product. As this performance optimum includes a certain buffer, a moderate increase in the forces acting on the axis will not usually lead to damage or faults. However, to maximize the service life of the drive and to ensure smooth operation, it is advisable to observe the recommended value and, where necessary, select a more robust linear actuator. In doing so, you ensure that power peaks do not cause the average axial force to be significantly exceeded.

In the fifth and final step of selecting the appropriate linear actuator for an application, we now check whether the selected model can deliver the required output power. To do so, we determine the output power (Pmax) and compare it with the required maximum mechanical power.

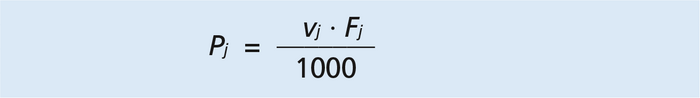

For each cycle step, the mechanical power can be calculated using the following formula:

For each linear actuator stage, the maximum value must be below the specified limit (Pout_max ≥ Pm).

In our example, the maximum power is:

Therefore, configurations with four stages must be excluded.

You are in the process of selecting a linear actuator and need a data sheet that you can't find anywhere on our website? Or you have already selected a linear actuator, but you are still unsure which of the motors from our product range would be the ideal combination partner for the planned application?

The sales engineers at FAULHABER will be happy to advise you. We will help you develop a perfectly tailored solution for all applications where particular requirements such as specific ambient conditions or mechanical constraints need to be taken into consideration.