To ensure reliable operation and a long service life for your application, it is important to select the linear motor that best suits and ideally fulfills your requirements. This tutorial will help you to determine the parameters that are important when calculating and selecting a linear motor. This will help you find the right linear drive from the FAULHABER portfolio for your project.

The FAULHABER experts show you step-by-step how to determine the relevant parameters for selecting a linear motor.

Below you will find out:

1. Which key figures you need to calculate the required speed profile for your application.

4. Why a practical test is indispensable even with precise calculation.

To calculate a linear motor and select the right drive, in addition to the size of the required model you also need to know how much power the motor can and should provide in the specific application case. For this reason, it is essential to determine a speed profile early on: You can then use this as the basis for calculating the required peak and continuous forces as well as the temperature development in the linear motor.

A meaningful speed profile, which maps the various load movements of the axis in the application case, forms the basis for selecting a linear motor.

To determine the movement properties required for this profile, you first need to answer the following four questions:

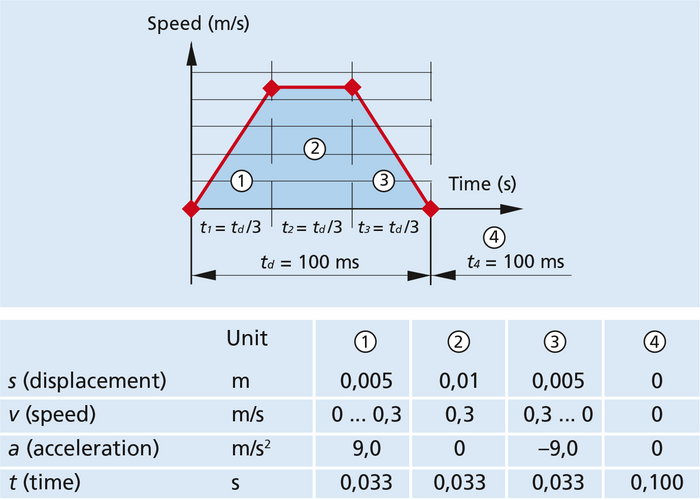

Using this data, you can calculate the individual speed profile of the linear motor for the concrete application situation. Unless otherwise prescribed by the application, the most common speed profiles are triangular or trapezoidal. In the following application example, the calculation is based on a trapezoidal profile.

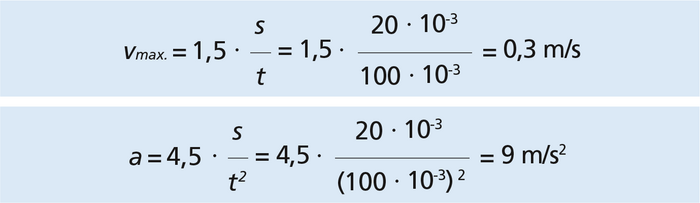

Here, let us assume a total mass of 500 g that needs to be moved 20 mm in 100 ms on a slope having a rising angle of 20°. To select a linear motor for this application, we will use a trapezoidal speed profile.

Detailed view: Calculation of the speed and acceleration for part 1

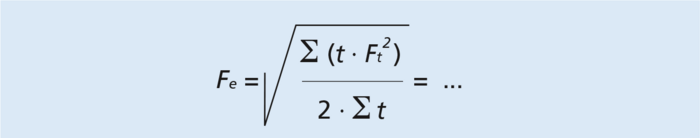

The peak force is the highest one achieved during the motion cycle. The continuous force, however, describes the force which a linear motor can and must apply in continuous operation.

To ensure that the selected model is suitable both for long-term use and for potential load peaks, it is advisable to additionally calculate the peak and continuous forces beforehand when selecting a linear motor.

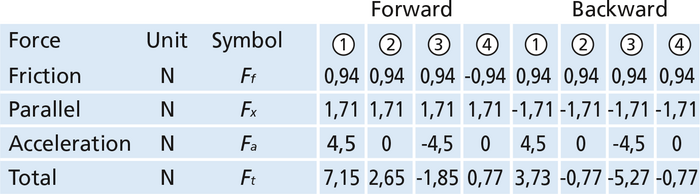

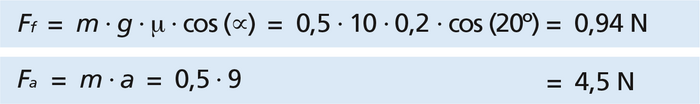

If we continue to assume a linear motor with a load of 500 g and a friction coefficient of 0.2, this initially results in these three forces for this application case.

Detailed view: Calculation of the friction and acceleration forces for part 1

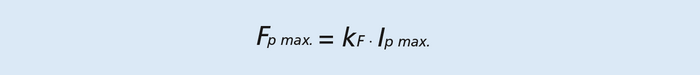

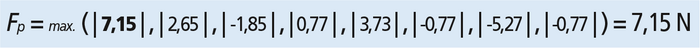

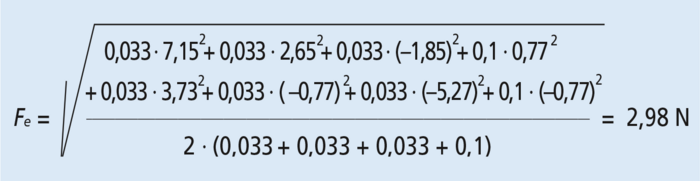

Now that the forces of the three parts of the profile are known, the required peak and continuous forces of the linear motor can be calculated in the next step.

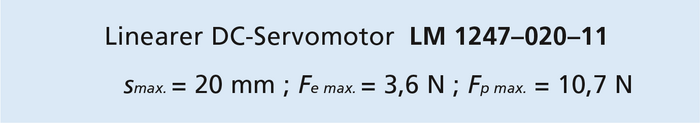

With these two values, it is now possible to find the right motor for the concrete application case. This results in the following calculation for selecting a linear motor for our application example:

To ensure the performance capability of the linear motor as well as a long service life of the overall system, a correct coil drive is essential.

The temperature of the coil winding is a key consideration here: If the coil becomes hot during continuous operation, it is not only the resistance that increases, but also the risk of the coil burning out. If you have already calculated the required continuous force for the selection of a linear motor, it is worth taking this into consideration when checking the temperature development at the coil.

To calculate the temperature, the following parameters must be known:

As the temperature of the coil winding is always calculated for continuous operation - i.e. with regard to prolonged stress in everyday operation - all of these values relate to rated operation.

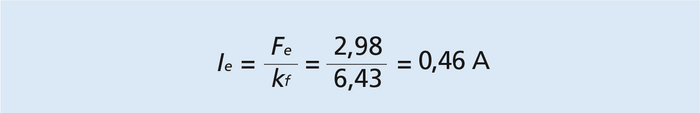

For this example, we assume a force constant kF equal to a continuous force of 6.43 N/A. The formula shows the result value of the calculation of the motor continuous current.

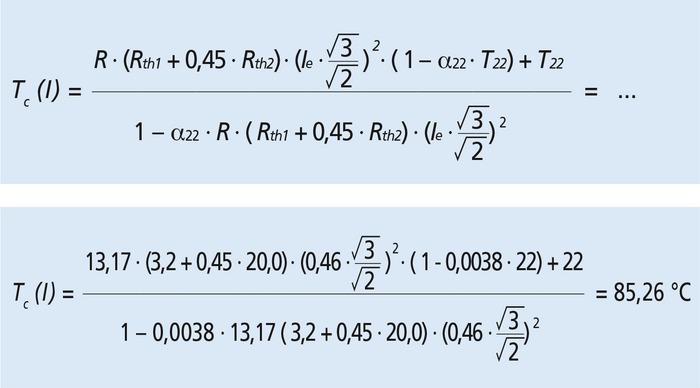

With an electrical resistance of 13.17 as well as a total thermal resistance of 23.2 °C/W (Rth1 + Rth2) and a reduced thermal resistance Rth2 of 55% (0.45 · Rth2), this in turn results in the following coil temperature in rated operation:

Our expert Mario Zecchin introduces you to the most common errors with linear motors and how to avoid them in order to maximize the efficiency and service life of your drive system.

Find out about what you have to consider in terms of wiring and supply voltage, why long wires or a small distance between motors could cause problems or what could happen if there's magnetic attraction between the screw and the rod.

Although intensive preparation and precise calculation are indispensable when selecting a linear motor, ultimately even the most thorough calculation is no substitute for the practical test: Numerous environmental factors that can affect the operation of the linear motor only become apparent in the application.

As soon as you begin making preparations for the purchasing decision, we therefore recommend that you document all parameters of the planned application - including all calculations on which you will base the selection of your linear motor. In this way, you can more easily identify potential discrepancies between your favored model and the application situation, and all the more quickly find a linear motor that precisely matches the requirements of your application.

You are in the process of selecting a linear motor and need a data sheet that you can't find on our website? Or you have already created a speed profile and calculated all required forces as well as the temperature development of the linear motor, but you are still unsure which of our motors best meets these parameters? No problem: The experts from FAULHABER will gladly advise you in all matters regarding the selection of your linear motor.