Some of the recent research activities in the area of electric motor drives for critical applications (such as aerospace and nuclear power plants) are focused on looking at various fault tolerant motor and drive topologies.

After discussing different solutions, this paper focuses on a miniature PM stepper motor design which falls in this fault tolerant category by providing an increased redundancy.

Safety critical systems are taking on increasing importance in the industrial world. Some examples of such systems are aerospace, transportation, medical and military applications, and nuclear power plants. These all accommodate a number of electric motor drives installed to a point where the plants rely heavily upon them. Any failure in these drives may cause catastrophic failures in the plants, which may be very costly in term of human resources and capital cost, and clearly undesirable. Techniques behind most of the electric drives on the market today are not adequate for safety-critical applications. Therefore, there is a need to improve the survivability of critical systems given the increasing dependence on them, and the serious consequences of their failure. One of the common tools used in the design of safety critical systems is redundancy. Ideally, many fault-tolerant systems should mirror all operations; that is, every operation should be performed on two or more duplicate systems, so if one fails the other can take over. Therefore, redundancy within the system is an essential aspect.

The specifications of a fault tolerant motor include:

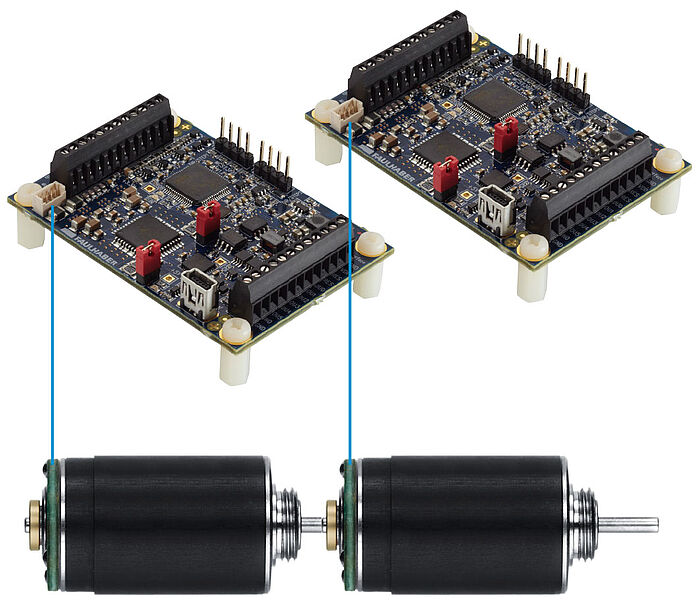

Coupling two motors on the same shaft (Figure 1) is what comes normally to one’s mind first. Although its implementation is straightforward, this solution presents several limitations to be considered:

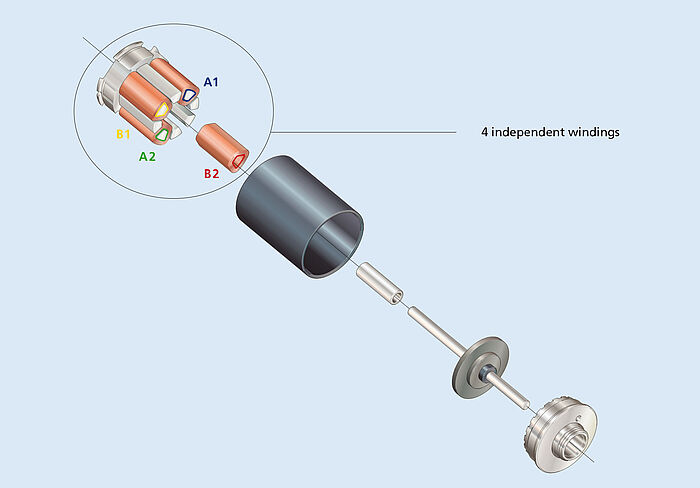

The existence of FAULHABER Disc Magnet motors simplifies the quest for redundancy capability. By default, this patented motor design features 4 windings which are normally connected by pair to form a Two-Phase stepper motor. A customised solution letting the 4 windings independent from each other creates two Two-Phase PM stepper motors with physically and electrically isolated phases which are the key to achieve a failure free system (Figure 2). The windings are only partially magnetically coupled and the redundant configuration leads to only a torque reduction of 30% when compared to the standard motor configuration at equivalent dissipated power. With proper heat sink and phase current increase, the same output torque can be reached.

The specific and patented design of some existing small miniature motor (down to Ø6mm) meets, with very little adaptation, the specifications for a fault-tolerant, robust, reliable motor with the degree of redundancy which is crucial in safety-critical applications that rely on the failurefree operation of electric motor drives.

Reference: Fault Tolerant Motor Drive System with Redundancy for Critical Applications N. Ertugrul, W. Soong, G. Dostal and D. Saxon. The University of Adelaide