For decades, we have been a driving force in the development of application-specific drive solutions and have set benchmarks across a wide range of markets. Our ability to anticipate future trends and adapt our production to new requirements makes us the ideal partner when it comes to developing innovative solutions together and bringing them to market quickly.

With an exceptionally short time-to-market, new dimensions, and perfectly matched features for robotics, the FAULHABER BXI is a prime example of the efficiency of this process. With this motor, we are introducing the most powerful integrated drive system in our portfolio to date – a direct response to our customers’ needs. Together with them, we develop and manufacture specific drive solutions for a new generation of robotic applications.

The FAULHABER BXI was developed specifically for the high demands placed on joints in current and future robotics applications. The drive system consists of a unit comprising a motor, integrated planetary gearhead, and high-resolution encoder. Its strength lies in its compactness: maximum performance in minimum space.

When connected to the FAULHABER MC5010 motion controller, a perfectly coordinated system is created for torque-sensitive, high-precision positioning tasks with simultaneous motor protection and easy commissioning thanks to Motion Manager software.

Two robust, shielded M12 electronic interfaces for motor supply and encoder ensure connection to the controller.

The internal rotor design with 21 pole pairs, a slotted stator, and iron-core winding ensures low cogging torque and high torque density.

The flat, space-saving aluminum housing guarantees corrosion resistance without coating and ensures optimized cooling. Additional advantages include low weight and high torque density.

A low mechanical time constant and low moment of inertia, combined with optimized heat dissipation and iron-core winding, ensure high short-term overload tolerance.

A lightweight, low-backlash planetary gearhead (2 stages in 1) with needle bearings reliably ensures optimal torque transmission.

The integrated 15-bit SSI absolute encoder, with line driver and compensation algorithm, handles commutation and positioning simultaneously – and is insensitive to interference.

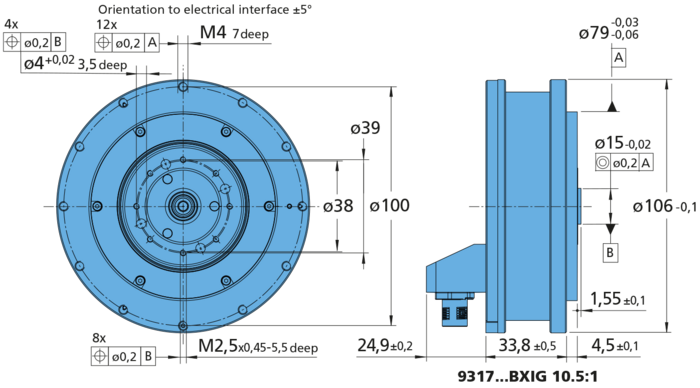

The Series 9317 BXI G internal rotor motor combines robustness and compactness, setting new standards. Its high maximum torque of up to 20 Nm enables effortless dynamic movements for fast response times and precise motion control. With a voltage range up to 50 V, the available interfaces, and a length of only 34 mm, the BXI is easy to integrate. Perfect for applications where every millimeter, every gram, and above all, power counts, e.g., as an articulated joint drive for humanoid robots.

Mechanical specifications

Mass: 987 g

Reduction ratio: 10.5:1

Electrical specifications

Absolute encoder with Line Driver

Operating voltage: 5 V ±10 %

Protocol: SSI

Resolution: 15 Bit

Voltage range: Motor, DC 0 ... 50 V

Direction of rotation: reversible

Operating temperature range

Ambient temperature: -25 … 85°C

Max. temperature:

- Motor / housing: 100°C

- Winding, max. permissible 125°C

Max. torque, up to 20 Nm

Max. power output, up to 270 W

Max. phase current, up to 13 A

No-load speed: 114 min-1

No-load current phase, rms 0.577 A

No-load voltage, DC 24 V