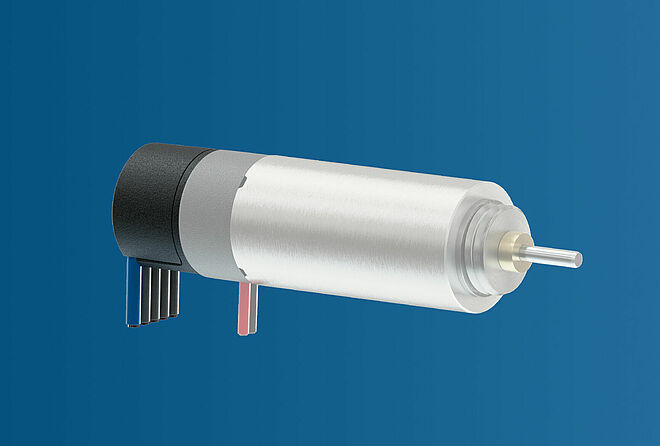

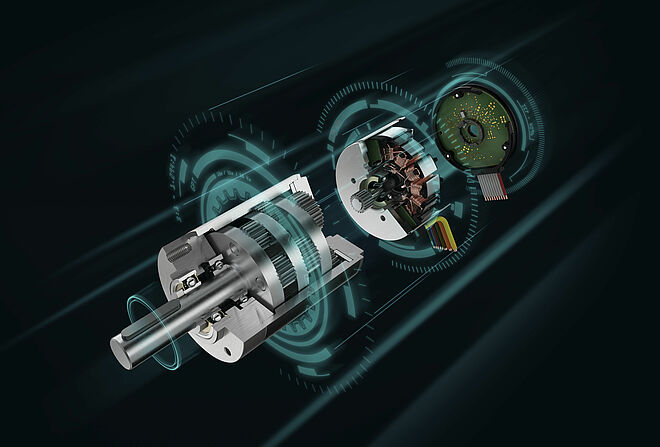

Based on proven gearhead technology, the two new variants offer optimized geometries for increased load capacity, improved dynamics, and maximum performance. Featuring three or four gear stages, a wide range of reduction ratios, and an operating temperature range from -30 °C to +120 °C, they are highly versatile and ideally suited for larger drives with dynamic motion profiles.

Powerful and uncompromisingly robust

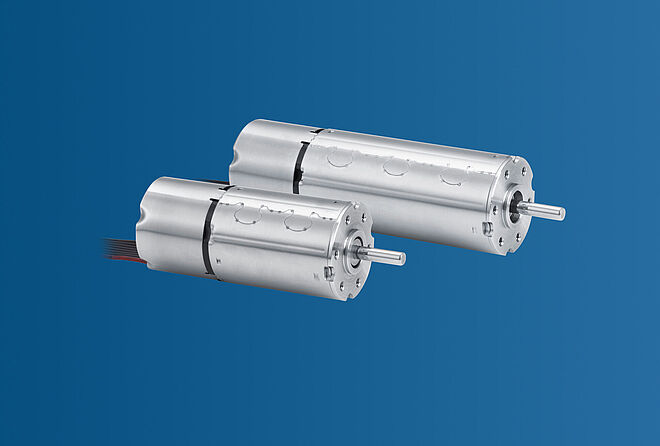

Both HT versions—the 22GPT HT and 32GPT HT—feature a full stainless steel housing that ensures outstanding robustness, stability, and resistance to external influences. This design enables high radial and axial load capacities, allowing for reliable performance and extended service life even under harsh operating conditions such as sudden load changes or emergency stops. These gearheads can indeed support accidental peak torque of up to 14 Nm for the 22GPT HT and 18 Nm for the 32GPT HT.

22GPT HT and 32GPT HT are performing particularly well in combination with larger and more powerful motors for intermittent operation, achieving respectively torque up to 5 Nm and 10 Nm. The optimized input speed range allows full exploitation of the motors’ dynamic capabilities without compromising performance, making the HT gearheads particularly suitable for applications demanding both strength and speed. Thanks to their excellent ability to handle high radial and axial forces, they are also well-suited for use in demanding applications where mechanical interface integrity is critical. Typical backlash is 0.8° for the 22GPT HT and 0.6° for the 32GPT HT, enabling precise and repeatable positioning in a wide range of use cases.

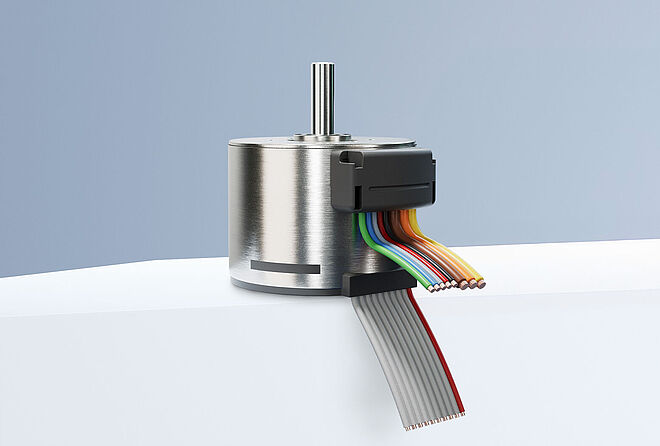

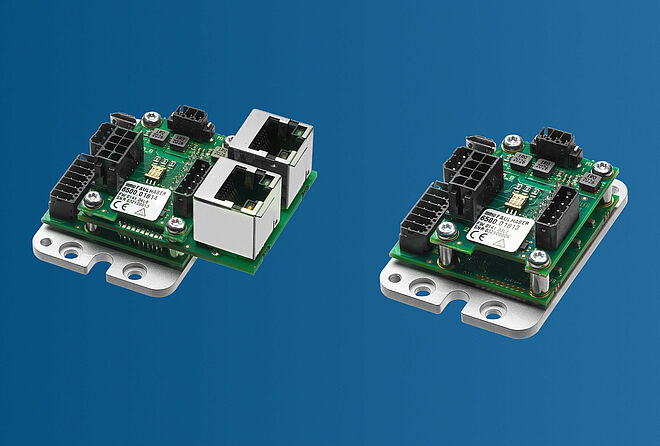

A particular highlight is the combination with stepper motors—a rare but powerful technology pairing for demanding positioning applications. A wide selection of standard options enables flexible system integration.

Typical application areas include inspection robots, electric grippers, robotic systems, exoskeletons, rehabilitation devices, industrial automation, semiconductor handling, and many other sectors where precision and performance are required in compact spaces.